Electromagnetic induction, a core principle in physics, is fundamental to understanding how induction helps in heat transfer. The efficiency gains observed in induction heating systems, often exceeding those of traditional methods, are driving adoption across industries, including applications researched at institutions like the National Renewable Energy Laboratory (NREL). These systems leverage the principles elucidated by pioneers such as Michael Faraday, demonstrating that the alternating magnetic fields generated by an induction coil induce eddy currents within a conductive material, leading to rapid and localized heating – a process vital for applications ranging from manufacturing processes to thermal management in semiconductor fabrication facilities.

Image taken from the YouTube channel Fluxtrol , from the video titled Power Transfer Factor In Induction Heating .

Imagine a world where heat is delivered with laser-like precision, targeting only the necessary areas and minimizing wasted energy. This is the promise of induction heating, a technology quietly revolutionizing numerous industries.

Induction heating stands apart from traditional methods due to its surprisingly efficient heat transfer process. In fact, some applications achieve efficiencies exceeding 90%, a stark contrast to the significant energy losses inherent in conventional heating systems.

Understanding Heat Transfer

Heat transfer, at its core, is the movement of thermal energy from one place to another. Traditional heating methods like furnaces or resistance heaters rely on indirect heat transfer. They generate heat externally and then transfer it to the target object through conduction, convection, or radiation.

Induction heating, however, takes a different approach. It generates heat directly within the material itself. This direct application of energy is the key to its exceptional efficiency.

Induction Heating: A New Paradigm

The fundamental difference lies in how energy is delivered. Instead of heating the surroundings and waiting for the target to absorb the heat, induction heating turns the target itself into the heat source.

This method not only accelerates the heating process but also drastically reduces energy waste. Less energy is lost to the environment, resulting in lower operating costs and a smaller environmental footprint.

Thesis Statement

Induction heating offers significantly greater heat transfer efficiency compared to traditional methods. This is due to direct energy application, precise control, and minimal heat loss to the surrounding environment. As we delve deeper, we will explore the underlying principles, practical applications, and the undeniable advantages of this innovative technology.

Understanding Induction Heating: A Deep Dive into the Process

Having established the compelling advantages of induction heating over traditional methods, it’s crucial to delve into the underlying science that makes this efficiency possible.

Induction heating operates on principles distinct from conduction, convection, and radiation, offering a fundamentally different approach to heat generation and transfer. This section will explore the key elements that define induction heating and illuminate its unique operational mechanisms.

What is Induction Heating?

At its core, induction heating is a non-contact heating process that leverages electromagnetic induction to generate heat within an electrically conductive material.

Unlike traditional methods that rely on external heat sources, induction heating transforms the material itself into the heat generator. This is achieved by placing the target material within a varying electromagnetic field.

This distinguishes it from:

-

Conduction: Heat transfer through direct contact.

-

Convection: Heat transfer through the movement of fluids (liquids or gases).

-

Radiation: Heat transfer through electromagnetic waves.

Induction heating bypasses these indirect methods, directly energizing the target material for rapid and efficient heating.

The Role of Electromagnetic Fields

The creation and manipulation of electromagnetic fields are fundamental to the induction heating process.

The principle governing this interaction is Faraday’s Law of Induction, which states that a changing magnetic field induces a voltage in any conductor within that field.

In induction heating, an alternating current (AC) is passed through a conductive coil, creating a fluctuating electromagnetic field around the coil. The frequency of the AC current determines the characteristics of the electromagnetic field.

The alternating nature of the current is critical because a static magnetic field would not induce a continuous current flow in the target material.

Eddy Currents: The Heat Source

When a conductive material is placed within the alternating electromagnetic field, the changing magnetic flux induces circulating electrical currents within the material. These currents are known as eddy currents.

Think of it like a transformer, where the induction coil is the primary winding and the workpiece is a single-turn secondary winding.

These eddy currents flow in closed loops within the material, following paths that minimize resistance. The magnitude of the induced eddy currents depends on factors such as the strength of the electromagnetic field, the frequency of the AC current, and the material’s electrical conductivity.

The distribution of these eddy currents is not uniform throughout the material, a phenomenon we will explore later in relation to the "skin effect."

Joule Heating: Converting Current to Heat

The flow of eddy currents through the conductive material inevitably encounters resistance. This resistance, inherent to the material’s atomic structure, impedes the flow of electrons, causing them to collide with atoms in the material’s lattice.

These collisions convert the electrical energy of the eddy currents into thermal energy, resulting in the heating of the material. This phenomenon is described by Joule’s Law of Heating, which states that the heat generated is proportional to the square of the current, the resistance of the material, and the time the current flows.

Mathematically, this is expressed as:

P = I^2 * R

Where:

- P is the power (heat) generated.

- I is the current (eddy current).

- R is the resistance of the material.

Therefore, the higher the eddy current and the greater the resistance, the more heat is generated within the material. This direct conversion of electrical energy into heat within the workpiece is what gives induction heating its characteristic efficiency.

Heat Transfer Mechanisms: Direct and Efficient

Having established the foundation of induction heating – the generation of electromagnetic fields and the induction of eddy currents – we now turn to how this translates into efficient heat transfer.

The efficiency of induction heating is not solely due to how the heat is generated, but also where and how quickly it is delivered to the material.

Direct Energy Application: A Key to Efficiency

The most significant advantage of induction heating lies in its direct energy application. Traditional heating methods, such as gas furnaces or resistance heaters, rely on heating an intermediate medium (air, water, etc.), which then transfers the heat to the target material.

This indirect process inevitably leads to energy loss through radiation, convection, and conduction to the surrounding environment. Induction heating bypasses this inefficient step by generating heat directly within the material itself. The alternating electromagnetic field induces eddy currents within the conductive material, and these currents then dissipate energy as heat due to the material’s inherent electrical resistance (Joule heating).

Imagine heating a metal rod with a torch versus placing it inside an induction coil. With the torch, much of the heat is lost to the surrounding air, and only a fraction is actually absorbed by the rod. In contrast, the induction coil heats the rod from within, minimizing heat loss and delivering energy precisely where it is needed.

This direct energy application results in significantly faster heating times and reduced energy consumption.

The Impact of Skin Effect on Heat Distribution

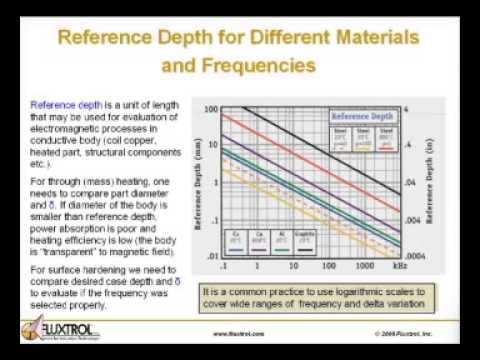

A crucial phenomenon influencing heat distribution in induction heating is the skin effect. This effect dictates that the density of the induced current is greatest near the surface of the material and decreases exponentially with depth.

The higher the frequency of the alternating current used, the shallower the penetration depth of the current. In simpler terms, higher frequencies result in surface heating, while lower frequencies allow for deeper penetration and more uniform heating.

Therefore, understanding the skin effect is critical for tailoring the heating process to specific material properties and application requirements. For example, surface hardening of steel requires high-frequency induction to concentrate heat on the surface, creating a hard, wear-resistant layer. Conversely, through-heating of a large metal billet would require a lower frequency to ensure uniform temperature distribution.

The material itself also plays a role. Materials with higher electrical conductivity will exhibit a shallower skin depth compared to materials with lower conductivity at the same frequency. Careful consideration of both frequency and material properties is crucial for optimizing the heating process.

Role of Thermal Conductivity

The thermal conductivity of the material being heated plays a vital role in how efficiently heat is distributed throughout the part. Materials with high thermal conductivity, like aluminum and copper, will quickly conduct heat away from the surface, promoting a more uniform temperature distribution.

Conversely, materials with low thermal conductivity, like some steels and ceramics, will exhibit a steeper temperature gradient between the surface and the interior. This means that the surface heats up faster, but the heat takes longer to reach the center.

Choosing the appropriate frequency and heating time is crucial to avoid surface overheating or incomplete heating of the workpiece’s interior.

The Importance of Temperature Control

Precise temperature control is paramount in induction heating, as it directly impacts both the efficiency and the quality of the final product. Sophisticated control systems monitor the temperature of the material in real-time and adjust the power output of the induction heater accordingly.

This feedback loop ensures that the material reaches the desired temperature quickly and accurately, without overheating or underheating. Precise temperature control minimizes energy waste and ensures that the material undergoes the desired metallurgical or physical changes.

Moreover, precise temperature management allows for repeatable and consistent heating cycles, essential for maintaining product quality in high-volume manufacturing environments. Advanced control systems can also be programmed to perform complex heating profiles, allowing for precise control over the heating rate, holding time, and cooling rate. Such levels of control enable induction heating to be precisely tailored to the particular demands of different materials and procedures.

Quantifying the Efficiency: Induction vs. Traditional Methods

While the principles of direct energy application and the skin effect highlight the inherent advantages of induction heating, the real proof lies in the numbers. Let’s delve into how its efficiency stacks up against traditional heating technologies.

Efficiency Gains: A Comparative Analysis

Induction heating consistently demonstrates superior efficiency ratings when compared to conventional heating methods. Gas furnaces, for instance, typically operate at efficiencies ranging from 70% to 85%. Resistance heaters fare somewhat better, reaching efficiencies of 80% to 95%.

However, induction heating can achieve efficiencies of 80% to 90% at the very minimum, and well over 90% is possible. This means a significantly larger portion of the energy consumed is actually converted into useful heat within the target material, minimizing waste.

The source of the wasted energy varies. In gas furnaces, heat is lost through exhaust gases and incomplete combustion. Resistance heaters lose energy through radiation and convection to the surrounding air.

In contrast, induction heating minimizes these losses by directly inducing heat within the material itself. This leads to a dramatic reduction in wasted energy.

Energy Savings and Cost Reduction: Real-World Impact

The higher efficiency of induction heating translates directly into substantial energy savings and cost reductions. The exact magnitude of these savings depends on the specific application, material being heated, and operating parameters.

However, the overall trend is clear: companies that switch to induction heating can expect to see a noticeable decrease in their energy bills. In many scenarios, the initial investment in induction heating equipment is quickly recouped through energy savings alone.

For example, a case study of an automotive manufacturer switching from gas-fired furnaces to induction heating for hardening gears showed a 40% reduction in energy consumption. This not only lowered operational costs but also significantly reduced the company’s carbon footprint.

Applications of Industrial Heating

Induction heating is rapidly becoming the go-to technology in numerous industries. Its efficiency is a key factor in this widespread adoption.

In the automotive industry, induction heating is used for hardening gears, axles, and other critical components. The aerospace industry employs it for heat treating aircraft parts, while the manufacturing sector utilizes it for processes like brazing, soldering, and shrink fitting.

These industries are experiencing significant gains using induction heating.

In each of these applications, induction heating delivers precise, controlled heat, resulting in improved product quality, reduced cycle times, and lower energy costs. These advantages are making induction heating the preferred choice.

Power Electronics: The Key to Optimizing Efficiency

The efficiency of induction heating systems is not solely determined by the physics of electromagnetic induction. The power electronics that control and drive the process play a crucial role.

Modern induction heating systems utilize sophisticated power electronics to precisely control the frequency and amplitude of the alternating current supplied to the induction coil. This allows for fine-tuning the heating process to match the specific material and application requirements.

Advanced control algorithms optimize the energy transfer, minimizing losses and maximizing efficiency. Furthermore, modern power electronics enable features like automatic frequency tuning, which ensures that the system operates at its optimal resonant frequency, maximizing power transfer and efficiency.

These advancements in power electronics have significantly improved the efficiency and reliability of induction heating systems, making them an even more attractive alternative to traditional heating methods.

companies that switch to induction heating can expect to see a noticeable decrease in their energy bills. In many scenarios, the initial investment in induction heating equipment is recouped through energy savings within a reasonable timeframe, making it a financially sound and environmentally responsible choice. But how does this theoretical efficiency translate into tangible benefits in everyday applications? Let’s explore the diverse landscape where induction heating shines, from the familiar comfort of our kitchens to the demanding environments of heavy industry.

Real-World Applications: From Kitchens to Industries

The beauty of induction heating lies not only in its efficiency but also in its versatility. It’s a technology that seamlessly transitions from heating a pot of water in your kitchen to melting tons of metal in a foundry. This adaptability stems from the precise control and localized heat generation inherent to the process.

Induction Cooktops: A Household Revolution

Induction cooktops have revolutionized home cooking, offering a faster, safer, and more energy-efficient alternative to traditional electric or gas stoves. Unlike conventional stovetops that heat indirectly through a heating element, induction cooktops generate heat directly within the cookware itself.

This direct heat transfer results in remarkably rapid heating times, bringing water to a boil in a fraction of the time it would take on a gas or electric stove.

Furthermore, induction cooktops are significantly safer. The surface of the cooktop remains relatively cool, reducing the risk of burns. They also offer precise temperature control, allowing for delicate simmering or high-heat searing with ease. The efficiency of induction cooktops translates to lower energy bills and a more responsive cooking experience.

Induction Furnaces: Powering Industry

Moving beyond the home, induction furnaces are indispensable tools in various industrial processes. These furnaces utilize powerful electromagnetic fields to melt, heat treat, or sinter metals with exceptional precision and efficiency.

Industries such as automotive, aerospace, and manufacturing rely heavily on induction furnaces for processes like melting aluminum, steel, and other metals.

The precise temperature control offered by induction furnaces is crucial for achieving desired material properties. It allows manufacturers to tailor the microstructure of metals, ensuring optimal strength, durability, and performance.

Moreover, induction furnaces are significantly cleaner and more environmentally friendly than traditional fuel-fired furnaces. They eliminate the emissions associated with combustion, contributing to a cleaner and more sustainable manufacturing process.

Harnessing Magnetic Materials for Enhanced Efficiency

The efficiency of induction heating can be further optimized through the strategic use of magnetic materials. Certain magnetic materials, when incorporated into the inductor coil or placed near the workpiece, can enhance the electromagnetic field strength and improve the coupling between the coil and the material being heated.

This improved coupling results in more efficient energy transfer and faster heating times. Ferrite cores, for example, are commonly used in induction heating systems to concentrate the magnetic field and minimize energy losses.

By carefully selecting and integrating magnetic materials, engineers can fine-tune induction heating systems to achieve maximum efficiency and performance for specific applications. These materials play a crucial role in directing and intensifying the electromagnetic field, ensuring that energy is delivered precisely where it’s needed, minimizing waste and maximizing the effectiveness of the process.

Induction & Heat Transfer: FAQs

Here are some frequently asked questions about the efficiency of induction heating and its role in heat transfer.

What makes induction heating so efficient?

Induction heating directly generates heat within the object being heated. This bypasses the need to heat an external source, minimizing energy loss and making the process incredibly efficient. Because induction helps in heat transfer, less energy is wasted heating the surrounding environment.

How does induction transfer heat differently from a stovetop?

Traditional stovetops first heat the burner, which then heats the pan. Induction heating, on the other hand, uses electromagnetic fields to induce heat directly into the pan itself. This direct method leads to faster and more controlled heating. The key is that induction helps in heat transfer by acting directly on the object.

Can induction work with any type of cookware?

No, induction heating only works with cookware made of ferromagnetic materials, such as cast iron or some stainless steel. These materials react with the electromagnetic field to generate heat. The type of cookware used determines if induction helps in heat transfer.

What are some common applications of induction heating?

Induction heating is used in a wide range of applications, including cooking, heat treating metals, and even medical procedures. Its precise control and efficiency make it ideal for processes requiring rapid and targeted heating. Induction helps in heat transfer within these systems.

So, there you have it! Hopefully, you’ve got a better grasp of how induction helps in heat transfer and why it’s such a game-changer. Now go forth and impress your friends with your newfound knowledge!